Material Testing Lab Insights: Discover the Science Behind Project Resilience

Wiki Article

Advancements in Material Testing for Improved High Quality Assurance

In today's fast-paced and affordable industries, guaranteeing top notch materials is critical to success. As technology proceeds to breakthrough, so does the requirement for much more innovative material testing methods. From non-destructive screening methods to automated systems, the area of material screening has actually seen amazing advancements. In this conversation, we will certainly check out several of the latest trends in product screening, consisting of making use of advanced sensor modern technologies, the combination of information analytics, and the duty of man-made intelligence. These growths not only guarantee improved quality control however additionally hold the potential to change markets throughout the board. So, allow's dive into the globe of innovations in material testing and uncover how these technologies are shaping the future of top quality guarantee.Non-Destructive Checking Approaches

Non-Destructive Screening Approaches play an essential duty in ensuring the integrity and quality of materials without compromising their structural integrity. These approaches are employed in different markets, including construction, aerospace, and production, to discover and determine problems or anomalies in materials or structures. By making use of non-destructive screening technicians, designers and methods can evaluate the properties, characteristics, and efficiency of materials without creating any type of damage.One commonly made use of non-destructive testing technique is ultrasonic screening (UT) UT includes the usage of high-frequency sound waves to identify defects such as fractures, gaps, and incorporations in materials.

Non-destructive screening methods give beneficial information concerning the top quality and reliability of products, making sure that they fulfill the called for specs and requirements. By implementing these strategies, markets can enhance their quality control procedures, minimize the threat of failing or crashes, and inevitably supply more secure and extra dependable products to customers.

Automated Testing Systems

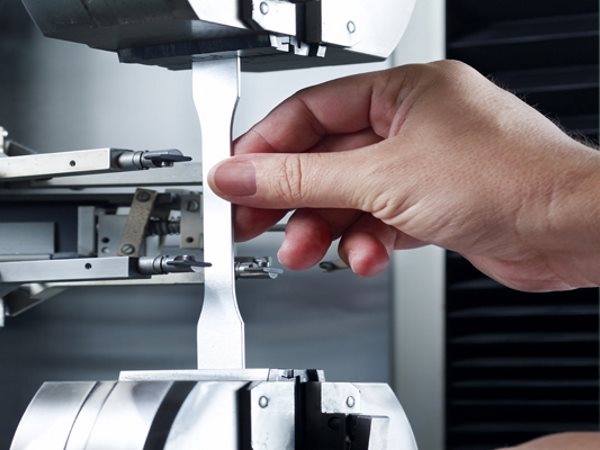

Automated screening systems have reinvented the area of material testing, providing effective and exact techniques for reviewing the quality and stability of materials. These systems utilize advanced modern technologies and algorithms to automate the screening process, decreasing human error and increasing productivity.One key advantage of automated screening systems is their capability to carry out tests at a much faster rate than manual screening techniques. With making use of robotics and advanced software program, these systems can carry out multiple examinations simultaneously, significantly lowering the moment needed for testing huge sets of products.

In addition, automated testing systems offer a greater level of precision and accuracy contrasted to hands-on screening. They can do tests with consistent criteria, making sure that the results gotten are reliable and reproducible. By getting rid of human subjectivity and variability, these systems give a much more objective analysis of material top quality.

Furthermore, these systems are equipped with innovative sensors and detectors that can identify even the tiniest problems or inconsistencies in material homes. This enables very early detection of prospective concerns, allowing suppliers to take rehabilitative actions before the materials are made use of in important applications.

In addition to their performance and precision, automated testing systems likewise boost security in product screening. By minimizing human involvement in potentially unsafe testing procedures, these systems lower the threat of accidents and injuries, ensuring a safer working atmosphere.

Advanced Sensor Technologies

With the assimilation of sophisticated sensor modern technologies, product screening systems have actually achieved also greater levels of precision and effectiveness (material testing lab). Advanced sensing unit modern technologies play a vital duty in boosting the quality assurance procedure by providing real-time and accurate data throughout product testing. These sensors can discovering and determining different physical homes such as temperature level, pressure, vibration, and stress, enabling a comprehensive evaluation of the material's behavior under different conditionsAmong the vital innovations in sensor modern technologies is the advancement of wireless sensing units. These sensing units eliminate the need for cumbersome wiring and enable seamless data transfer, improving the total adaptability and wheelchair of the screening process. Additionally, cordless sensing units can be easily incorporated into existing material screening systems, making them an affordable solution for updating and improving testing capacities.

Artificial Knowledge in Material Screening

Expert system has changed the field of material screening, bringing extraordinary degrees of accuracy, performance, and anticipating abilities to the quality control procedure. With the ability to analyze huge quantities of information and recognize patterns that might go undetected by human operators, AI algorithms have actually significantly improved the dependability of product screening treatments.Among the key benefits of utilizing AI in material testing is its capacity to anticipate material behavior under various conditions. By training AI versions on historical data, researchers can create predictive designs that can approximate the performance of materials in real-world scenarios. This permits producers to maximize material option and style, reducing the demand for time-consuming and expensive experimental processes.

Furthermore, AI can enhance the product and automate testing process, enhancing effectiveness and reducing human error (material testing lab). AI-powered systems can autonomously bring out screening procedures, gather and examine data, and generate extensive reports. This not just conserves time yet likewise ensures consistent and trustworthy outcomes

Furthermore, AI can discover and evaluate material issues or abnormalities with high accuracy. By contrasting examination results to predefined requirements, AI algorithms can quickly identify variances and sharp operators to potential concerns. This very early detection of flaws aids avoid malfunctioning products from getting in the manufacturing procedure, ultimately boosting product quality and consumer satisfaction.

Assimilation of Data Analytics

Data analytics plays an essential duty in the assimilation of product testing procedures, enabling suppliers to draw out important understandings and make notified choices. By making use of sophisticated analytic strategies, producers can analyze huge volumes of information collected throughout product testing to recognize patterns, patterns, and abnormalities that may influence the quality and efficiency of their products.Assimilation of discover here data analytics in product screening allows manufacturers to monitor and review different criteria and variables throughout the screening process. This consists of factors such as temperature level, pressure, strain, and various other environmental problems that can influence the habits and characteristics of materials. By assessing this information, suppliers can gain a deeper understanding of exactly how various variables interact and affect the efficiency of their products.

Furthermore, information analytics assists in recognizing possible site defects or weak points in products, enabling producers to take proactive steps to attend to these problems before they cause product failures or safety risks. This positive technique can significantly improve the overall quality control procedure and improve client satisfaction.

In addition to identifying flaws, information analytics can likewise enhance material testing procedures by recognizing locations of enhancement and recommending adjustments in the testing procedures. By examining historic data, manufacturers can identify patterns and trends that can assist them streamline their screening procedures, minimize expenses, and improve effectiveness.

Verdict

Non-destructive testing approaches, automated testing systems, advanced sensing unit innovations, and the combination of information analytics have all played a considerable role in boosting the precision and efficiency of product testing procedures. In addition, the application of artificial knowledge in material screening has further added to the development of even more reliable and specific testing strategies.From non-destructive testing strategies to automated systems, the field of material screening has seen impressive improvements. Cordless sensors can be conveniently integrated right into existing product testing systems, making them a cost-efficient remedy for improving and upgrading screening capabilities.

Assimilation of information analytics in material testing permits producers to check and evaluate different criteria and variables throughout the screening procedure. Non-destructive testing techniques, automated screening systems, progressed sensing unit innovations, and the integration of data analytics have all played a considerable duty in boosting the precision and efficiency of product screening procedures. Additionally, the application of synthetic knowledge in product testing has additionally added to the growth of even more reputable and specific testing methods.

Report this wiki page